Laboratory

The company has established a testing laboratory to undertake the following main testing tasks: incoming material performance testing, performance testing during product production, product warehousing and performance testing before products leave the factory. The test items include but are not limited to physical indicators (micrometer thickness, color difference test, appearance, weight, ink layer wear resistance test, bar code scanning, high and low temperature constant temperature and humidity test, product fall resistance test, vibration simulation transportation test, paper humidity test, ink sun protection and aging test, DuPont impact test compressive impact force, printing plate dot test, film anti-static test, film toughness flapping test, etc.).

Testing laboratory: Our laboratory covers an area of more than 40 square meters, with physical index testing room, sample retention area, archive area, etc., 37 kinds of laboratory equipment, laboratory testing instructions and relevant project testing standard documents developed to provide standard guidance for laboratory testing.

The laboratory has 2 laboratory operators with rich inspection experience, who are responsible for incoming material performance testing, performance testing during product production, product warehousing and performance testing before product delivery.

Calibration and management of experimental equipment: The laboratory equipment is managed, maintained and maintained by a special laboratory operator. Before the end of each year, a third-party equipment testing agency is invited to conduct external calibration of our equipment, ensure the effectiveness and standardization of our testing equipment, and provide an effective third-party equipment calibration qualification report before putting into use.

Equipment name: UV accelerated aging test chamber

Model: TF-8506-A

Operating environment: temperature 23 ± 2 ℃ humidity 60 ± 5%

Temperature control range: room temperature - 200 ℃

Function introduction: aging and yellowing resistance, testing of finished products after UV treatment, sun resistance and high temperature resistance

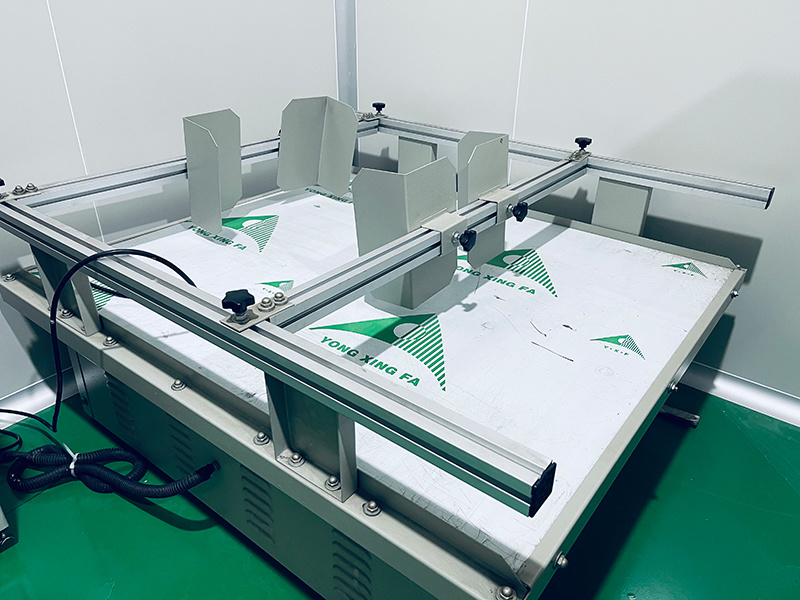

Equipment name: simulated transport vibration platform

Model: HD-A521

Standards: EN71 ANSI, UL, ASTM, ISTA

Test object: carton

Function introduction: test the influence and change on the quality or structure of the carton after being subjected to certain frequency and amplitude during transportation

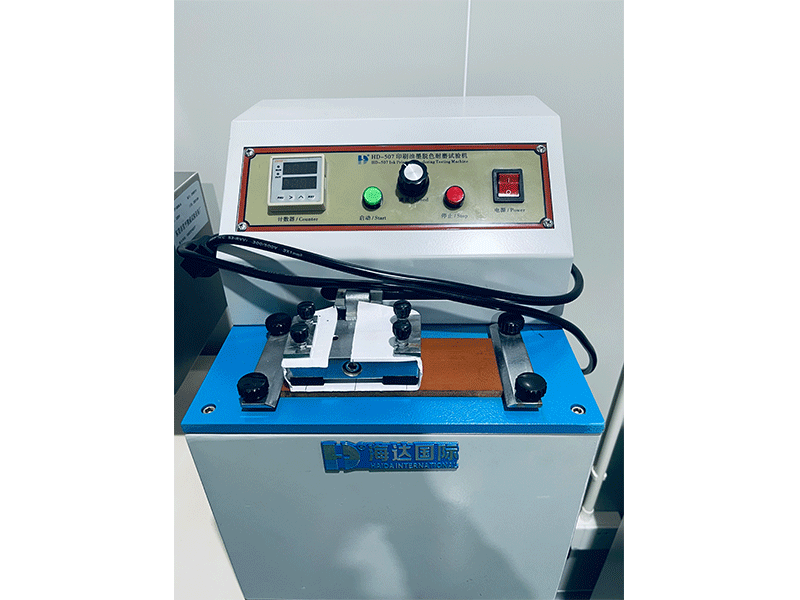

Equipment name: Ink decolorization abrasion resistance tester

Model: HD-507

Design standards: JIS-5071-1, TAPPI-UM486, GB7706

Test object: printing ink layer of printed matter

Function introduction: The abrasion resistance tester is used to test the abrasion resistance of printing ink layer of printed matter, the abrasion resistance of photosensitive layer of PS plate and the abrasion resistance of surface coating of related products. Effectively analyze the problems such as poor abrasion resistance, ink layer falling off, low printing resistance of PS plate and poor coating hardness of other products.

Equipment name: Programmable constant temperature and humidity testing machine

Operating environment: the room temperature is within the range of 0-55 ℃, the relative humidity is less than 80% RH, and it is far away from strong electromagnetic interference.

Test standards: GB2423.1-2008/IEC6008-2-1-2007, GB/T 2423.2-2008

Function introduction: mainly used to simulate the harsh high temperature, low temperature or damp heat environment that may be encountered during the transportation, storage and use of packaging materials; Or high temperature, low temperature, damp heat alternating environment, the material's high temperature resistance, cold resistance, damp heat resistance performance and possible damage life reduction.

Equipment name: film beating tester

Model: TF-JPDJ

Test object: PET, PVC, PP

Function introduction: It is applicable to film material flapping test to check the appearance damage degree of the test piece and judge the impact resistance and flapping strength of the film.

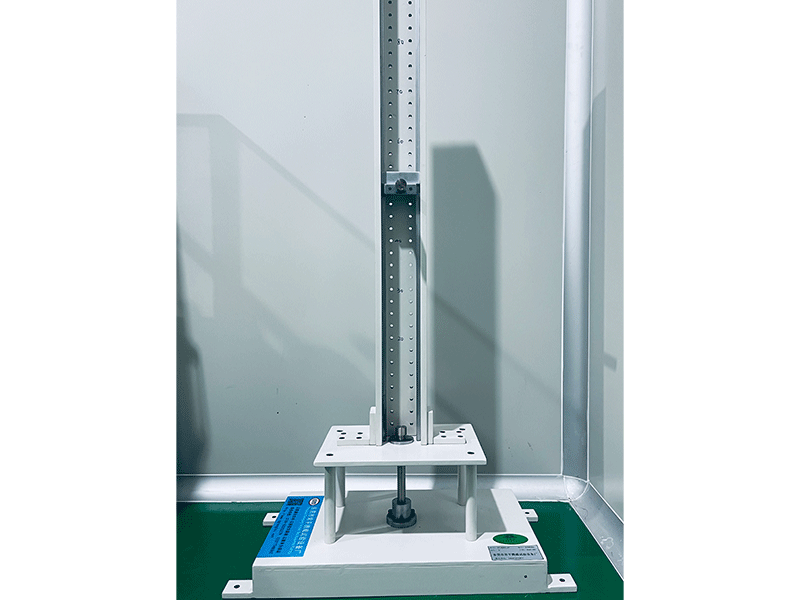

Equipment name: impact testing machine

Model: TF-4003-JP

Standards: JIS-K5400, K5640, ASTM-D2794

Function introduction: used to test the impact resistance of PET, PVC and PP materials. Place the test piece under the impactor of the machine, drop it with a heavy hammer of a certain height, and then check the damage, deformation or peeling.